Pasteurized Milk Preparation

Introduction

Pasteurized milk is a safe and widely consumed dairy product. It undergoes a heat treatment process to eliminate harmful bacteria while preserving essential nutrients. This process ensures milk stays fresh and safe for consumption. Understanding how pasteurized milk is prepared helps consumers and dairy professionals appreciate its significance in food safety.

Collection and Reception of Raw Milk

Sourcing Milk from Dairy Farms

Raw milk is collected from dairy farms and transported to processing facilities. Farmers ensure cows are healthy and follow proper milking practices. The milk is stored in sanitized, sealed containers to prevent contamination during transportation.

Initial Quality Checks

At the facility, milk undergoes initial quality checks. These include:

- Temperature Measurement: Raw milk should be below 45°F (7°C) to inhibit bacterial growth.

- Visual Inspection: Experts check for cleanliness and foreign particles.

- Sensory Evaluation: Milk is assessed for off-flavors or unusual odors.

Ensuring these standards helps maintain milk quality before further processing. Learn more about dairy hygiene standards set by regulatory authorities.

Clarification of Milk

Removing Impurities

Milk may contain dirt, hair, or other particles. Clarification removes these impurities using:

- Centrifugation: A high-speed process that separates heavy debris from milk.

- Filtration: Fine mesh filters help remove solid impurities.

These steps ensure clean milk enters the pasteurization process, reducing contamination risks.

Pasteurization: The Key Process

What is Pasteurization?

Pasteurization is a heat treatment that destroys pathogens without compromising milk quality. It prevents diseases such as tuberculosis and brucellosis, making milk safe to drink. Pasteurization guidelines outline the importance of this process.

Types of Pasteurization

High-Temperature Short-Time (HTST) Pasteurization

HTST is the most common method. It involves:

- Heating milk to 161°F (72°C) for at least 15 seconds.

- Rapidly cooling it to below 45°F (7°C).

This method balances bacterial elimination with nutritional retention. Read more about HTST pasteurization.

Low-Temperature Long-Time (LTLT) Pasteurization

LTLT is another approach. It requires:

- Heating milk to 145°F (63°C) for 30 minutes.

- Gradual cooling below 45°F (7°C).

This process is gentler, often used in smaller dairy farms. Learn about small-scale dairy pasteurization.

Homogenization: Ensuring Consistency

Why Homogenization Matters

Milk naturally contains fat globules that separate over time. Homogenization prevents this by:

- Breaking down fat globules into smaller, uniform particles.

- Distributing fat evenly throughout the milk.

This process enhances texture and shelf stability. Find out more about milk homogenization.

Cooling Process

Rapid Cooling for Freshness

Once pasteurization is complete, milk is rapidly cooled to below 45°F (7°C). This step is crucial to:

- Prevent bacterial growth.

- Maintain freshness and flavor.

Quick cooling extends milk’s shelf life and ensures safety.

Packaging and Labeling

Hygienic Packaging

Pasteurized milk is packaged in sanitized, airtight containers. Common options include:

- Plastic bottles

- Cartons

- Jugs

Proper packaging preserves freshness and prevents contamination.

Labeling Requirements

Labels provide crucial consumer information, including:

- Pasteurization method used

- Expiration date

- Storage instructions

Labels help consumers make informed choices about their dairy products.

Storage and Distribution

Cold Storage for Safety

Milk should be stored at temperatures below 45°F (7°C) to retain quality. Proper refrigeration:

- Prevents spoilage

- Maintains nutritional value

Retailers must follow strict storage guidelines. Learn about milk storage recommendations.

Efficient Distribution

Pasteurized milk is distributed through various channels:

- Grocery stores

- Supermarkets

- Local dairy farms

Proper transportation ensures milk reaches consumers fresh and safe.

Conclusion

Pasteurized milk preparation follows strict hygiene and safety protocols. From sourcing and pasteurization to packaging and distribution, every step ensures high-quality milk reaches consumers. By following regulatory standards, dairy producers maintain safety and nutritional value.

Understanding this process helps consumers appreciate the effort behind every glass of pasteurized milk. Explore more on dairy industry standards.

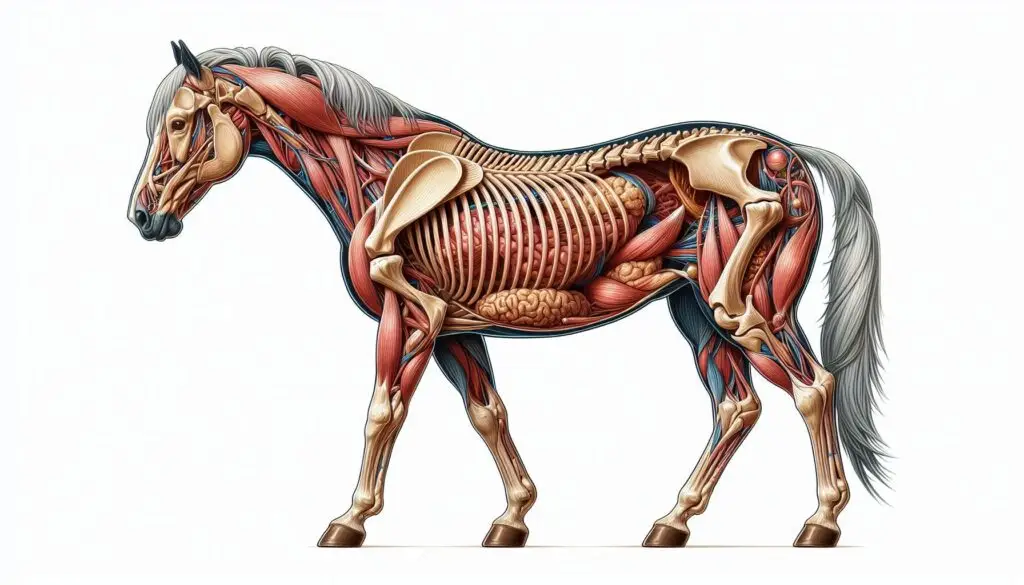

For more pearls of Vets Wisdom:

Estimating Sires: Progeny Testing and Threshold Models

Responses